Mantis HEX Deposition System

Mantis HEX Deposition System

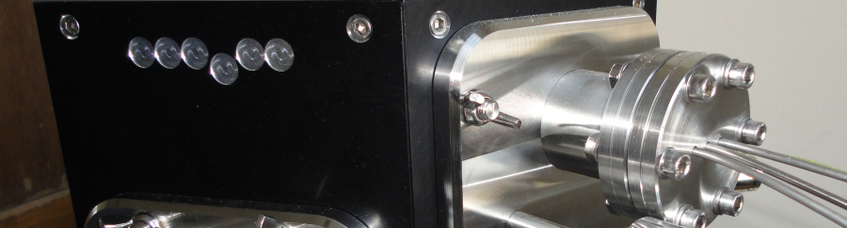

The Mantis HEX is a flexible system that allows for the deposition of thin layers under high-vacuum. It has a modular design and can be easily reconfigured with an arbitrary combination of e-beam, sputtering and thermal evaporation sources.

The vacuum chamber consists of a six-faceted frame with exchangeable panels which can be exchanged easily after removing a few wing nuts. Thus every intended configuration can be implemented within a few minutes.

Person in charge

Please contact Stephan Puchegger if you need further information. He will relay your request to the person currently in charge of the system.

Specifications

The sample stage is located at the top of the chamber with the samples facing down. Either a single 4" wafer or several smaller samples can be mounted. The sample stage can be rotated (2–20 rpm) in order to guarantee the uniformity of the deposited films. The sample stage can be lifted from the vacuum chamber and placed on a tabletop after turning it over. This allows for rapid and easy sample loading.

The following evaporation sources are available:

- 1 2" magnetron sputter source (for non-magnetic materials with a thickness of 1–6 mm and magnetic materials with a thickness up to 1 mm)

- 1 e-beam evaporator

- 2 single boat thermal evaporators which are suitable for both metals and organics/polymers

The system is equipped with quartz balance so that the deposition rate and amount can be controlled.